- Mine de-watering

- Ground water extraction, potable water dewatering

- Agriculture water well rising for irrigation

- Water supply wells in R.O. desalination plant applications

- Food processing

- Environmental monitoring

- Land stabilization

- Solar power systems

- Offshore rig fire water and service pumps

Advantages

- Cost-Effective

- Through-the-weave One Layer Design Without Layer Glue

- Great Adhesion and Tensile Strength

- NSF61 Potable Water Approved

- Long Life and Low Maintenance

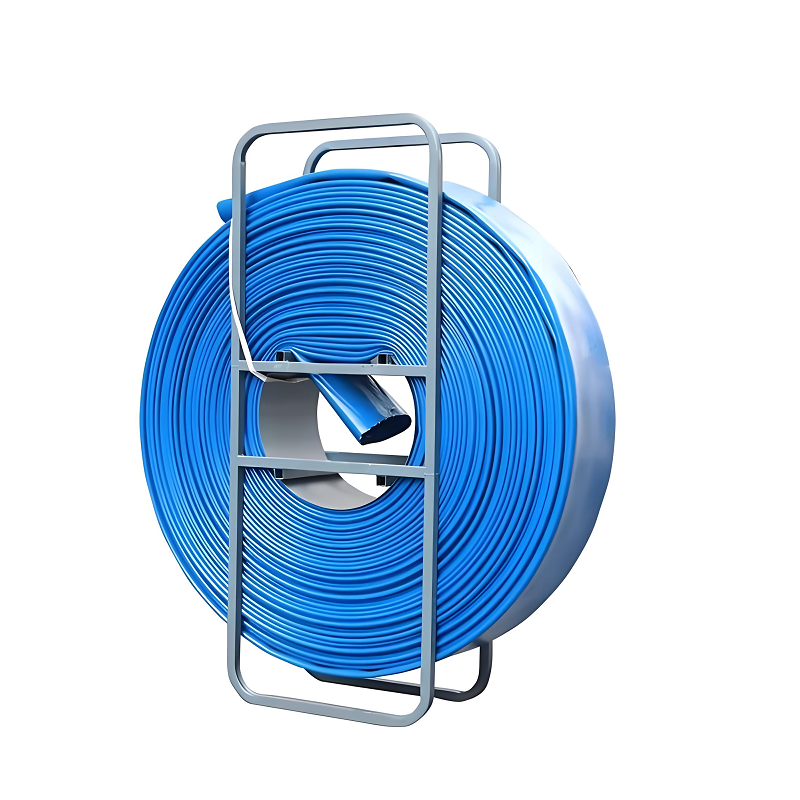

- Easy to Deploy and Retrieve

- Less Impact on the Environment

- High Working Pressure

Features

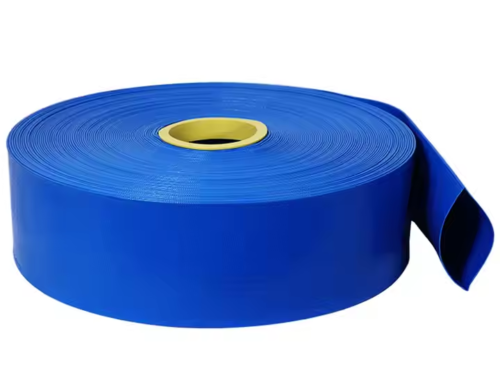

- Minone TPU Layflat hose is made from extruded thermoplastic polyether based polyurethane(TPU) with excellent wear & tear properties.

- The reinforcement is made from circular woven filament polyester yarn.

- The “extrusion through-the-weave” production method gives a very strong bonding between cover and lining as well as firmly encapsulating the woven polyester.

- The hose has high resistance against commonly used chemicals and has excellent resistance to UV radiation, hydrolysis and fungus degradation.

- The abrasion resistance of the TPU is one of the highest available, making the hose ideal for use in the extremely abrasive environment in open pit mines.

- The outer cover has been designed with extra thickness in order to add wear & tear material. This extends the useful lifespan of the hose.

- Extra abrasion resistance for rugged terrain and extreme conditions Resistant to oil and chemicals UV Stabilized

- Abrasion: 4000 DIN cycles

Minone Hose Data

| ID | Tolerance | Wall Thickness | Service Pressure |

Minimum Burst Pressure |

Weight | |||

| inch | mm | mm | inch | mm | psi | psi | lbs/ft | kg/m |

| 2″ | 51 | 51.0-53.0 | 0.071 | 1.80 | 250 | 750 | 0.28 | 0.42 |

| 2″ | 51 | 51.0-53.0 | 0.138 | 3.50 | 410 | 1230 | 0.47 | 0.70 |

| 3″ | 76 | 76.0-78.0 | 0.118 | 3.00 | 250 | 750 | 0.60 | 0.90 |

| 3″ | 76 | 76.0-78.0 | 0.126 | 3.20 | 410 | 1230 | 0.70 | 1.05 |

| 4″ | 102 | 102-104.5 | 0.110 | 2.80 | 200 | 600 | 0.72 | 1.08 |

| 4″ | 102 | 102-104.5 | 0.138 | 3.50 | 250 | 750 | 0.87 | 1.30 |

| 4″ | 102 | 102-104.5 | 0.142 | 3.60 | 300 | 900 | 0.94 | 1.40 |

| 4″ | 102 | 102-104.5 | 0.189 | 4.80 | 610 | 1830 | 1.27 | 1.90 |

| 5″ | 125 | 125-127.5 | 0.142 | 3.60 | 150 | 450 | 1.21 | 1.80 |

| 6″ | 152 | 154-157 | 0.126 | 3.20 | 150 | 450 | 1.27 | 1.90 |

| 6″ | 152 | 154-157 | 0.149 | 3.80 | 250 | 750 | 1.41 | 2.10 |

| 6″ | 152 | 154-157 | 0.165 | 4.20 | 300 | 900 | 1.68 | 2.50 |

| 6″ | 152 | 154-157 | 0.228 | 5.80 | 410 | 1230 | 2.28 | 3.40 |

| 6″ | 152 | 154-157 | 0.216 | 5.50 | 610 | 1830 | 2.14 | 3.20 |

| 8″ | 204 | 204-207 | 0.149 | 3.80 | 200 | 600 | 1.94 | 2.90 |

| 8″ | 204 | 204-207 | 0.157 | 4.00 | 250 | 750 | 2.28 | 3.40 |

| 8″ | 204 | 204-207 | 0.165 | 4.20 | 300 | 900 | 2.35 | 3.50 |

| 8″ | 204 | 204-207 | 0.165 | 4.20 | 410 | 1230 | 2.68 | 4.00 |

| 10″ | 254 | 256-259 | 0.165 | 4.20 | 200 | 600 | 2.68 | 4.00 |

| 10″ | 254 | 256-259 | 0.177 | 4.50 | 250 | 750 | 3.02 | 4.50 |

| 10″ | 254 | 256-259 | 0.197 | 5.00 | 300 | 900 | 3.69 | 5.50 |

| 12″ | 306 | 306-311 | 0.165 | 4.20 | 150 | 450 | 2.81 | 4.20 |

| 12″ | 306 | 306-311 | 0.197 | 5.00 | 200 | 600 | 3.48 | 5.20 |

| 14″ | 356 | 356-360 | 0.189 | 4.80 | 150 | 450 | 4.36 | 6.50 |

| 16″ | 406 | 406-410 | 0.197 | 5.00 | 100 | 300 | 4.56 | 6.80 |

| 16″ | 406 | 406-410 | 0.212 | 5.40 | 150 | 450 | 5.23 | 7.80 |

*All above technical data are FRI, pls confirm with Shanghai APT for more details.

Fast Delivery

FAQ

about shanghai APT

leadership for Hose Pipe Industry

Develop high efficiency hose and pipe technology.

Get In Touch

For any sales enquiries, questions or comments, please contact us by filling in the enquiry form. Alternatively, you can reach us here:

Mob/whatsapp: +86-13687112280

E-mail: sales@aptmachine.com