Digoliner G No-dig UV-CIPP Pipe Lining DN150~DN1800 Sewage Stormwater Pipline ASTM Standard

Description

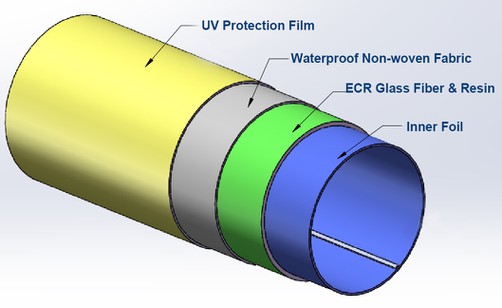

Shanghai APT Digoliner G UV CIPP Pipe lining is a process of weaving glass fibers into tubes, injecting or impregnating them with resin under vacuum, and pulling them into the original pipeline. Under the action of a UV lamp, the lining is cured into a lining tube with a certain strength to achieve the purpose of pipeline repair and reinforcement. Digoliner G provide exceptional strength and durability, ensuring long-lasting performance in challenging environments.

- Structural repair after pre-treatment of collapsed pipelines

- Internal reinforcement for non excavation repair such as pipeline rupture and leakage

- Structural damage repair of pipelines

- Pipeline anti-corrosion maintenance

- Meet and exceed ASTM Standards

- Structural Integrity

- Wear and Corrosion Resistance

- Radial Extensibility

- Smooth Surface

- Customizable Solutions

- Advanced Materials

Digoliner G UV CIPP Data

| Diameter | DN150mm(8″)-DN1800mm(70″) |

| Thickness | 3mm-15mm |

| Applications | Drainage pipe(sewage stormwater) |

| Cure Type | UV light |

| Blow Pressure | 150mBar-450mBar |

| Curing Speed | 15cm/min-150cm/min |

| Storage Air Compressors | Indoor Storage, 5-25℃,avoid light exposure |

Digoliner G UV CIPP Data Testing DATA

| Testing Items | Technical Requirements | Test Value |

| Bending Strength | ≥125Mpa | 200Mpa |

| Tensile Strength | ≥80Mpa | 90Mpa |

| Short-term Flexural Elastic Modulus | ≥8000Mpa | 15000Mpa |

| Long-term Flexural Elastic Modulus | / | 11400Mpa |

| Leaking Test | No leakage | No leakage |

| Creep Coefficient | / | 0.76 |

Fast Delivery

FAQ

about shanghai APT

leadership for Hose Pipe Industry

Develop high efficiency hose and pipe technology.

Get In Touch

For any sales enquiries, questions or comments, please contact us by filling in the enquiry form. Alternatively, you can reach us here:

Mob/whatsapp: +86-13687112280

E-mail: sales@aptmachine.com